Never let it be said that we guys, at BWL rest on our laurels, fail to adopt new technologies and do not move with the times.

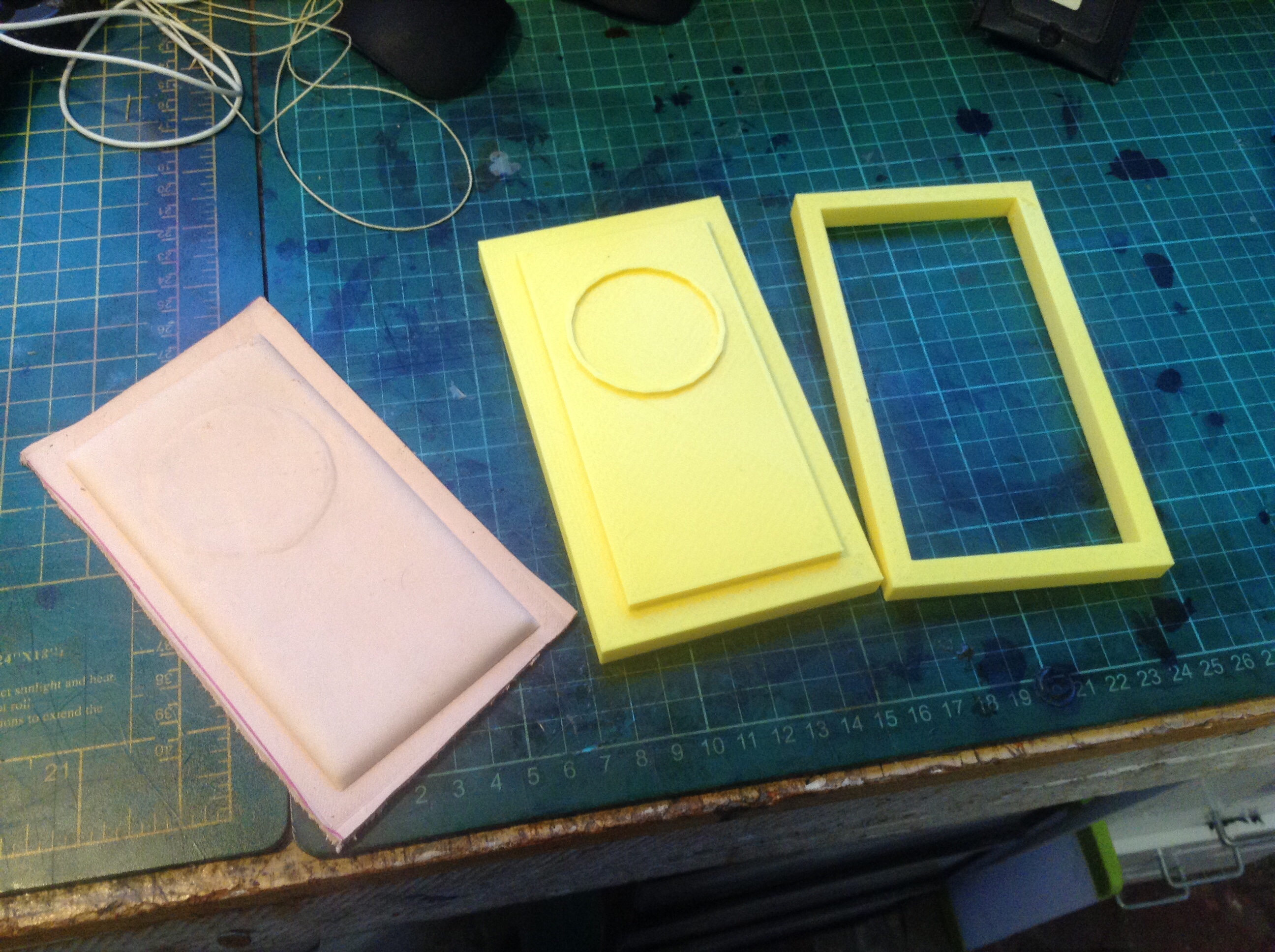

A long standing issue with making small wet moulded items is the time and cost of creating moulds. The same applies to embossing stamps, but more about them later. My eldest son treated me to a 3D printer for my 60th birthday. It was not long before I hit on the idea of using it to create one-off moulds for specific jobs. My Silva Compass Case being a good example. With a bit of fiddling with a CAD software program I produced a superb mould for the cases. Much more accurate than my earlier wooden version, it turns out correctly dimensioned case parts again and again, and when it finally breaks, I can print another!

perfect fit, time after time 👍😄

perfect fit, time after time 👍😄